Scroll sideways to see the full table

| Casing Size (in) | Casing Weight (Ib/ft) | Casing Nominal I.D./Drift (in) | Plug O.D. (in) | Plug I.D. (in) | Plug Set Length (in) | Pressure Rating (psi) | Temperature Rating (°F) | Drop Ball Size (in) | Ball in Place Size (in) |

|---|---|---|---|---|---|---|---|---|---|

| 3.5 | 9.3 | 2.992/2.867 | 2.725 | 0.730 | 6.8 | 10,000 | 275 | 1.650 | 0.900 |

| 4.5 | 11.6 | 4.000/3.875 | 3.620 | 0.900 | 8.3 | 10,000 | 2.125 | 1.25 | |

| 13.5 | 3.920/3.795 | ||||||||

| 15.1 | 3.826/3.701 | ||||||||

| 5.0 | 18 | 4.276/4.151 | 3.940 | 1.125 | |||||

| 5.5 | 17 | 4.892/4.767 | 4.375 | 9.0 | 8,000 | 1.5 | |||

| 20 | 4.778/4.653 | 10,000 | |||||||

| 23 | 4.670/4.545 | ||||||||

| 26 | 4.548/4.423 | ||||||||

| 6 | 22.3-24.5 | 5.200/5.075 | 4.840 | 1.375 | 10.0 | 8,000 | 1.650 |

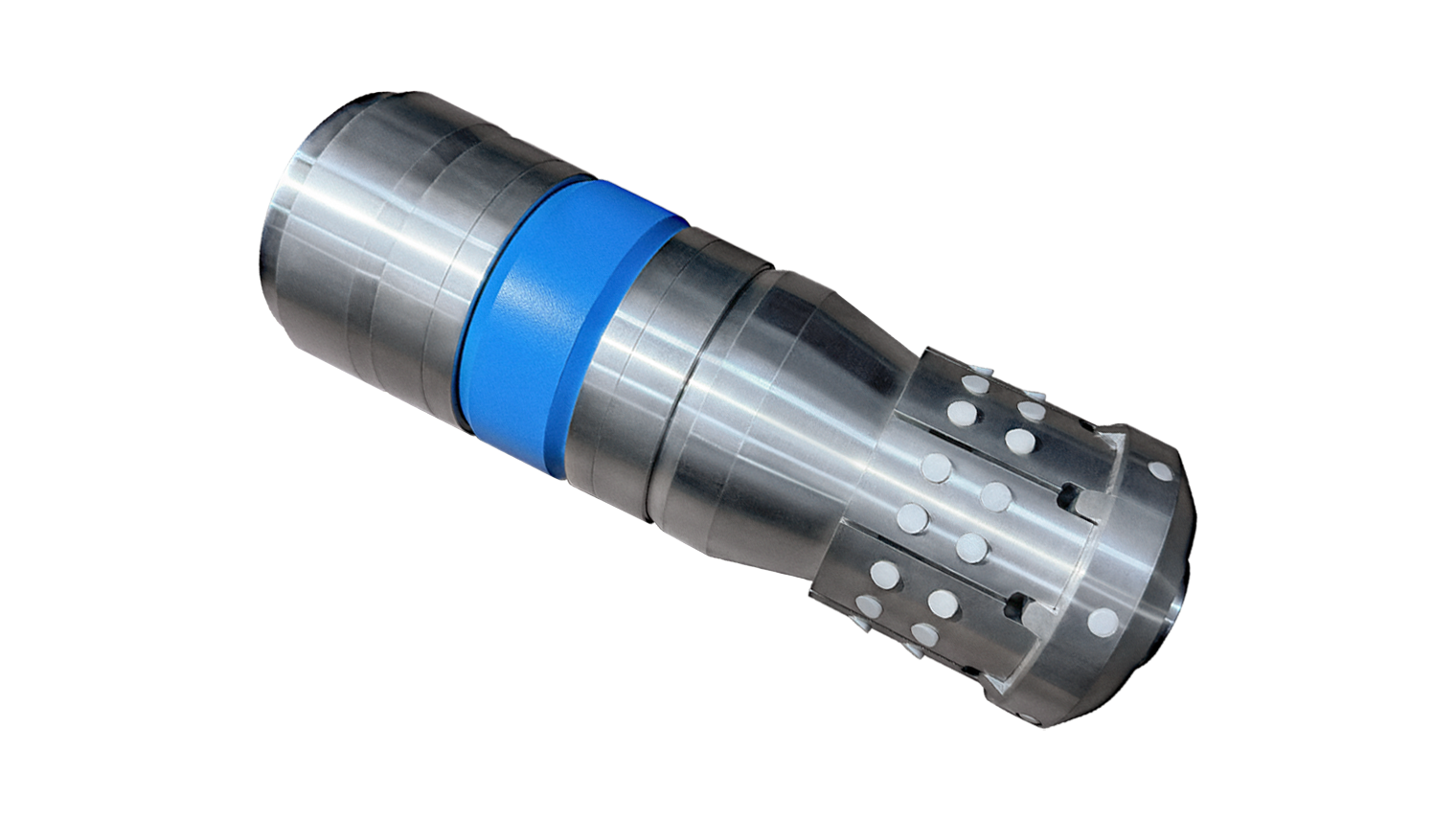

The patented Apollo Dissolvable Frac Plug™ from Shale Oil Tools utilizes advanced dissolvable metal technology and engineering design to achieve superior performance. Apollo plugs deploy reliably, dissolve predictably, and do not slip, enhancing completion efficiencies for Operators. Make-up is seamless with a simple two-piece adapter kit, compatible with industry-standard setting tools.

Dissolution is driven by time, temperature, and salinity (chloride content), occurring volumetrically based on the exposed surface area. To ensure the best performance, we offer the Apollo in various metallurgies and routinely collect and test customer water samples to determine the optimal metallurgy for their specific application.

To prevent slippage, the Apollo features a dissolvable sealing mechanism with an added ‘boost’ that enhances the seal by applying increased pressure. Its anti-pre-set mechanism ensures the plug can withstand the toughest conditions while running in without prematurely setting, either partially or fully.

Most dissolvable frac plugs on the market: