Scroll sideways to see the full table

| Casing Size (in) | Casing Weight (Ib/ft) | Plug O.D. (in) | Packer Bore I.D. (in) (after expending plug) | Pressure Rating Below (psi) | Pressure Rating Above (psi/screw) Brass/Steel | Temperature Rating (°F) |

|---|---|---|---|---|---|---|

| 4.5 | 11.6-13.5 | 3.700 | 1.500 | 8,000 | 1,025/1,500 | 275 |

| 5.5 | 17-20 | 4.500 | 1.900 | 575/835 | ||

| 20-26 | 4.400 |

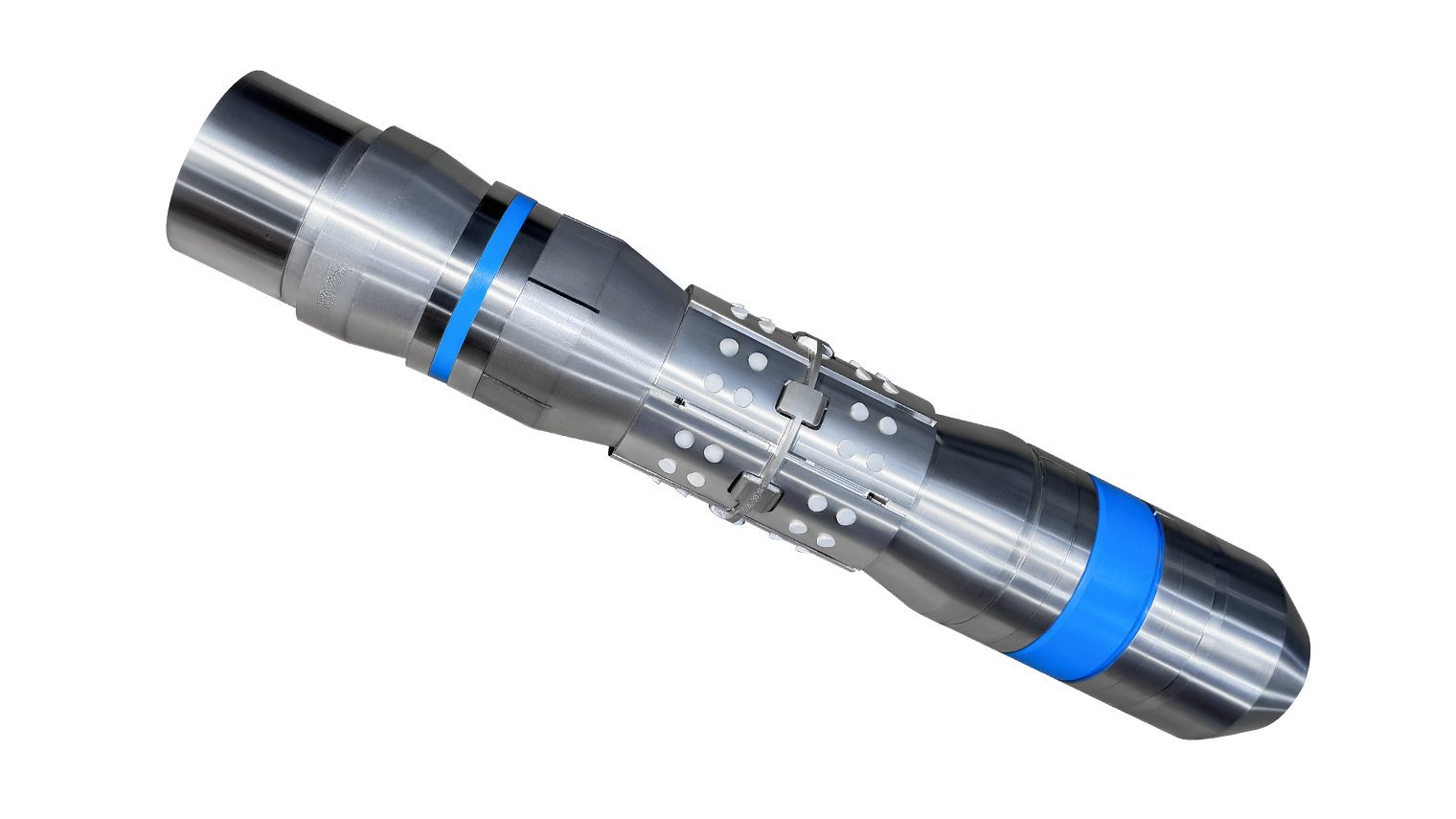

The patent-pending Atlas Dissolvable Packer™ from Shale Oil Tools provides temporary wellbore pressure isolation. Perfect for the installation of tubing, ESPs, gas lift, and other production equipment, the Atlas is designed to streamline your operations and improve efficiency.

Unlike traditional retrievable packers, the Atlas is engineered to be set deep within the well's curve, enhancing drawdown and increasing production with minimal risk. Its cutting-edge dissolvable technology eliminates the need for expensive retrieval trips, simplifying your workflow.

Additionally, the Atlas replaces the need for time-consuming milling operations often required with cast iron stops and bridge plugs. Enjoy a more efficient, cost-effective solution that reduces operational time and effort while delivering outstanding performance.